LaserEMobility

Laser based manufacturing in the eV sector

LASEREMOBILITY WORKSHOP 2024

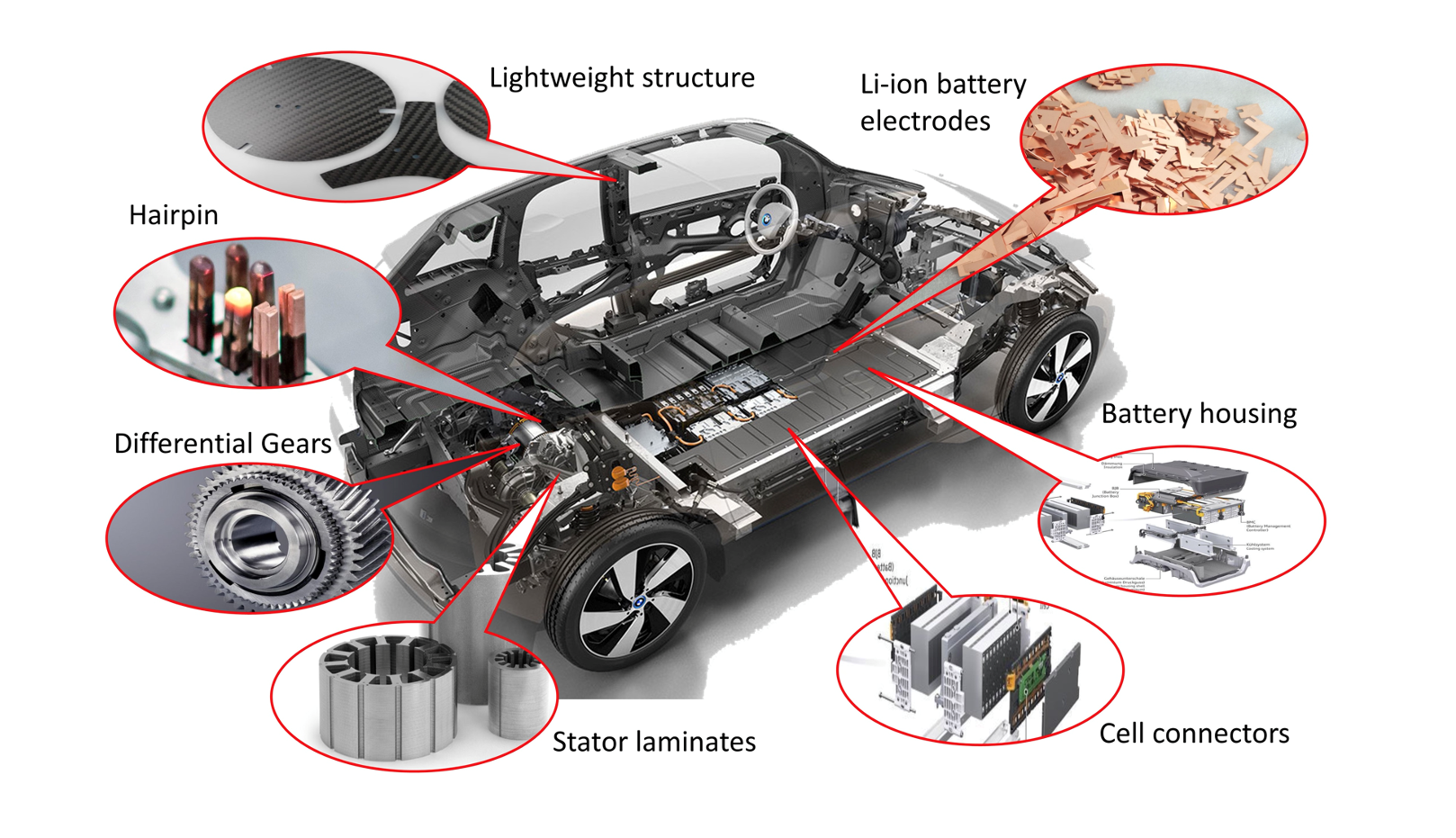

The contemporary e-drives are being used in a variety of vehicles and laser-based manufacturing is the convectional tool with subtractive, additive, assembly, and inspection processes are already employed for e-vehicle manufacturing. LaserEMobility promotes and increases the know-how in laser processing to respond to the high demand in e-vehicle manufacturing sectors.

KEYWORDS

E-mobility

Laser based manufacturing

E-drives

Battery

Mission

Laser manufacturing processes is a founding technology for electrical vehicle production and meets the industrial requirements of digitalized, flexible, adaptable and reliable manufacturing processes. Electrification is changing vehicles in terms of materials and design so that manufacturing processes should evolve to meet the new requests and the increasing demand of heat treatments and joining, cutting, ablation and texturing processes.

LaserEMoblity aims to gather scientific and industrial know-how of laser-based manufacturing processes for e-mobility applications such as stripping and welding of hairpins, cutting and texturing of Li-ion battery electrodes, welding of battery busbars and cutting of composite materials. Laser system developers and users are required to keep up with the ever-increasing demand in the production of electric vehicles. LaserEMobility arises from this necessity to accelerate intake of the laser use in manufacturing for the next generation of electric vehicles. LaserEMobility aims to bring together developers and system integrators and end users in an international network and to disseminate the main engineering tools to successfully apply lasers in the field of electric mobility.

- "Rete e know-how per le lavorazioni laser nel settore dei veicoli elettrici."

- "Laser: l'utensile digitale che aiuta l'elettrificazione della mobilità."

- "Dalla trazione elettrica al sistema di batterie, la produzione di veicoli con laser."

- "Fotoni per elettroni - Produzione della prossima generazione di veicoli elettrici."

Coordinatori e componenti fondatori

Corbinelli Rubino

Coordinatore industriale

Atop spa

Demir Ali Gökhan, Politecnico di Milano, Dipartimento di Ingegneria Meccanica

Corbinelli Rubino, Atop spa

Fortunato Alessandro, Università di Bologna, Dipartimento di Ingegneria Industriale

Michael F. Zäh, Technische Universität München, Institute of Machine Tools and Industrial Management (IWB)

Di Silvio Luca, Manz Italia

Lehmann Wolfgang, Raylase

è disponibile il white paper della sezione al link:

https://link.springer.com/chapter/10.1007/978-3-031-41163-2_12