DFT

Digital Factory Twin.

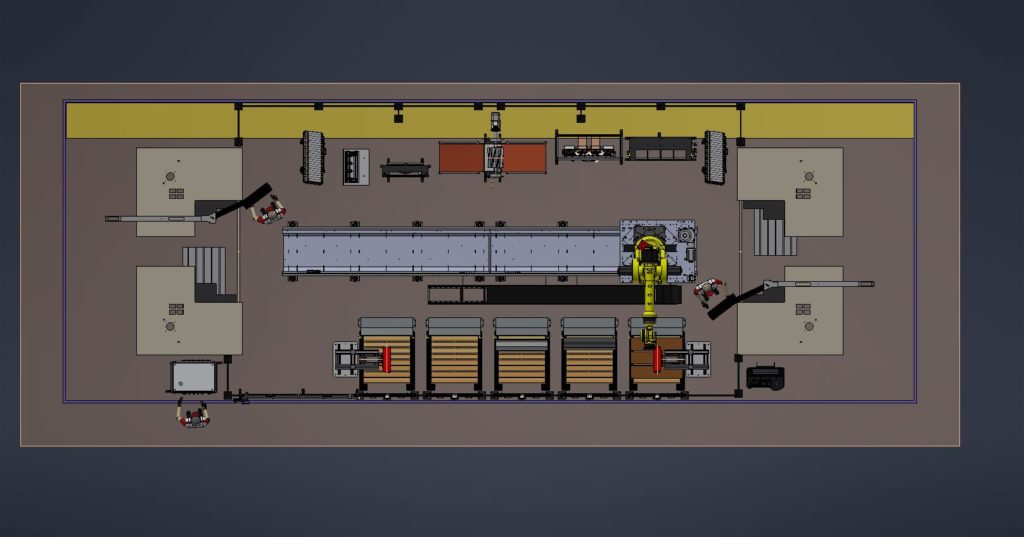

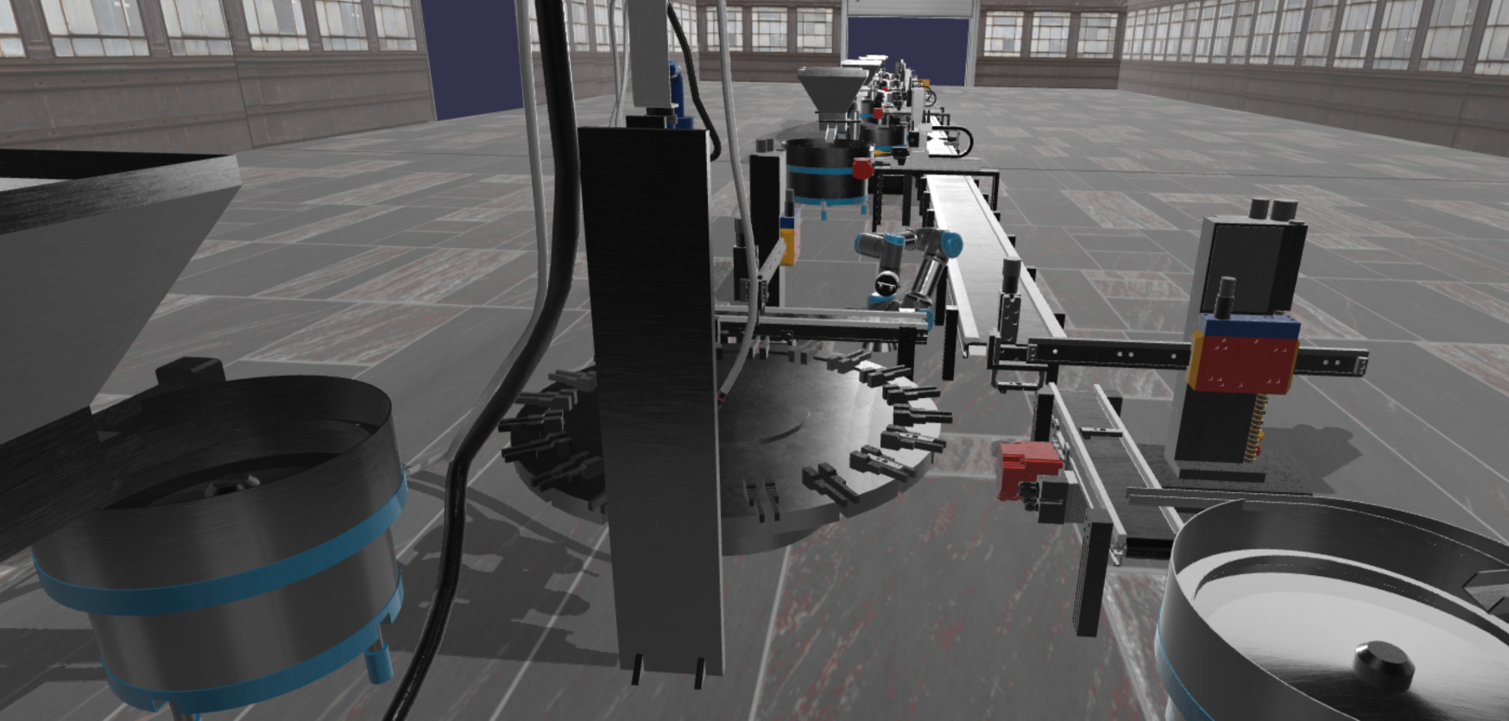

The industrial uptake of digital enabling technologies raises the need of technical competences to collect, structure, analyze, and exploit acquired data. The Section DFT (Digital Factory Twin) aims at disseminating Digital Twin enabling technologies and competences to support the design and management of industrial applications. Attention is devoted to advanced interfaces (e.g. Virtual Reality and Augmented Reality), and AI algorithms.

KEYWORDS

Digital Twin

Virtual Factory

Artificial Intelligence

Training

Mission

The wide adoption of digital technologies in factories yields a large amount of data, but the collection and analyses of these data ask for transversal competencies (mathematics, informatics, engineering) together with approaches and tools to design and operate a complex digital infrastructure. The addressed topic is based on the concept of Digital Twin (DT) coupled with a physical object to support analyses and decisions. In the manufacturing context, a DT can be linked to a product, a specific machine tool or process, a production system, or a whole factory.

Virtual models composing a DT can be employed to verify, validate, and evaluate the performance of the physical counterpart along its lifecycle phases. An effective DT for manufacturing needs:

- A reference framework to support interoperability and communications;

- Multi-scale data models for the representation of products, processes, systems, and their evolution;

- Synchronization between real and digital factory;

- Integration of advanced methodologies that can benefit from the DT potential.

DFT aims at aggregating a community of researchers together with technology providers and users to foster the development and adoption of DT-based analysis, elaboration, and decision support tools in academic and industrial contexts. In particular:

- The development of Factory DT to model the characteristics of products, processes, and systems for the productions of mechanical components;

- The integration of DT in the factory digital infrastructure by defining the required level of details and coping with the information and decision flows;

- The integration with methodologies and tools for the management of production systems;

- The development of transversal competencies for engineers as new professionals that will address the digitising of manufacturing companies;

- The use of advanced interfaces for training and evaluations in a virtual environment.

- "I modelli virtuali sono impiegati per la verifica, validazione e valutazione della controparte fisica"

- "Ricercatori, fornitori di tecnologie ed utilizzatori collaborano per adottare strumenti basati su DT di fabbrica"

Coordinatori e componenti fondatori

Sortino Francesco

Coordinatore industriale

CELADA SpA

Terkaj Walter, STIIMA-CNR

Sortino Francesco, CELADA SpA

Annoni Massimiliano, Politecnico di Milano, Dipartimento di Meccanica

Sortino Marco, Università di Udine, Dipartimento Politecnico di Ingegneria ed Architettura

Urgo Marcello, Politecnico di Milano, Dipartimento di Meccanica

Pessot Elena, Università di Siena, Dipartimento di Ingegneria dell’Informazione e Scienze Matematiche

Benedetti Fabiano, BeanTech srl

Maisto Saverio, Cluster COMET scrl

Zanelli Riccardo, Cluster COMET scrl

è disponibile il white paper della sezione al link:

https://link.springer.com/chapter/10.1007/978-3-031-41163-2_13